Supply chain management in eCommerce

Every product goes through a certain journey before it reaches its end customer. It is manufactured, quality checked, temporarily stored and finally (often several times) transported.

Each of these steps is part of the supply chain. Its proper management is therefore the basis of all logistics processes and largely determines the success of your business.

In our article, you will gradually learn what an example of an e-commerce supply chain looks like, how its quality is reflected in the business or tips for streamlining it.

What is the supply chain

A supply chain is a system made up of manufacturers, suppliers, vendors, carriers, people, activities, information and other resources. Supply chain management means overseeing and trying to improve the functioning of the above links so that the product is delivered at the required speed and quality.

Inefficiencies in the process can lead to reduced margins, turnover and customer satisfaction. Examples include out of stock due to temporary production failure at a single supplier or lengthy lead times caused by slow fulfilment.

The supply chain diagram of an online store differs from the traditional supply chain of brick-and-mortar stores. Compared to brick-and-mortar stores, products from the online store are shipped directly from the warehouse to the end customer. Of course, there are companies that use both channels for their sales, but a simplified example of a pure e-commerce supply chain might look like this:

How the supply chain makes business more efficient

As mentioned above, the quality of your supply chain affects the growth of your business. So what are the benefits of an efficiently managed supply chain?

Helps maintain the optimum quantity of products in stock

Based on the forecast of demand for your products, determine the re-order point for each SKU and re-order quantity of goods from your supplier when this threshold is reached. Also maintain sufficient safety stock* in your warehouse. Only in this way are you able to eliminate the risk of running out of stock. Conversely, overstocking leads to high storage and acquisition costs that do not contribute to your cash flow.

* Safety stock = the number of units of a specific product that need to be kept in extra stock for “just in case”

Accelerates the process across its links

By continuously analysing and optimising your supply chain, you reduce delays between the different parties involved.

- Does it take too long to produce your products? Negotiate better terms or find another supplier.

- Struggling with slow lead times? Analyze your warehouse location and move closer to your customers.

- Are you uncomfortable working with your current carriers? Contact a suitable competitor and find out their terms and conditions.

Reduces logistics costs

Thinking strategically about your logistics? Are you planning for the next 2 years? Are you gradually introducing optimization steps into your process? Poorly managed warehouse management, inappropriate warehouse location, high transport costs, inadequate warehouse processes or inadequate workforce reduces the overall profit of your business. Change the way you look at logistics. Don’t think of it as a “necessary” expense but as an opportunity to save money.

How to streamline the supply chain?

Online stores of all sizes always have plenty of “invisible” opportunities to improve their supply chain. Eliminating even a few small flaws can ultimately have huge benefits. Below you will find 6 tips to improve your supply chain.

1. Choose your supplier carefully

The manufacturer or supplier is the first link in the supply chain. Based on the nature of the goods you sell, choose one that can guarantee their fast, cheap and safe production. Ask the following questions when choosing a potential supplier:

- Where does the material for production come from?

- At what price is the supplier able to deliver the products to your warehouse?

- Is there a similar manufacturer closer to your warehouse?

- Do you have other suppliers in backup in case of temporary production failure at the current supplier?

- Is the supplier able to shorten lead times for manufactured products?

- Do you know when you will need to reorder stock? Set clear terms of cooperation with your supplier.

- Is your supplier able to assemble and package products to reduce the amount of work in your warehouse? How much does he charge for these services?

2. Order products based on demand forecast

Forecasting future demand allows you to react flexibly to changes in your supplier’s order quantities. Try to order your products on time and correctly. For more information on how to order your product inventory, see our article on Inventory Management.

3. Plan a shipping products to your warehouse in advance

Agree with your supplier on the terms of delivery of the products to your warehouse. If you have multiple warehouses, make sure that the correct quantity is scheduled to move to each one. Also make sure that each shipment contains all the mandatory documents for the chosen carrier.

4. Store received goods efficiently

The moment your goods arrive at the warehouse, ensure they are properly stocked. Ideally, store each SKU separately per position, this is the only way to ensure fast and accurate order picking. For example, if you are selling a red t-shirt that comes in sizes S, M, L, XL and XXL, you will need a minimum of 5 stock positions. How do I “stock up” correctly? An ABC analysis based on inventory turnover may be the answer.

5. Accelerate the lead time of the order to the customer

This point is the last link in the supply chain. It starts when the order is received into the warehouse system, followed by the picking, packing, handing over to the carrier and delivery to the customer. It is the speed of delivery that is increasingly a competitive advantage in today’s e-commerce world.

6. Make sure your customer knows the current status of the shipment

In addition to the physical movement of goods across the supply chain, there is also a need to ensure the transfer of up-to-date information on the status of the shipment. There must be a digital footprint for each handling. Only in this way are you able to analyse and improve the different parts of your supply chain. In this way, you can, for example, get accurate information on when your goods will be delivered to the warehouse or what your current stock levels are. Last but not least, you are also able to provide information about the status of orders to your customers.

Simplify your supply chain

Supply chain management is a complex and never-ending process. But it is the key to successfully scaling your business. By managing it effectively, you reduce the problems associated with manufacturing, transporting or storing products.

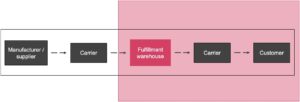

But there is a way to simplify your supply chain. Outsource part of your business to industry experts. In the case of fulfillment outsourcing, a diagram of your e-commerce store’s supply chain might look like this; the part highlighted in pink is the responsibility of the fulfillment partner.

In this model, you are only responsible for working with your manufacturer/supplier or communicating with end customers.

Is the step of establishing cooperation with a fulfillment specialist an important milestone for your business? Yes, absolutely. That is why it is absolutely essential to entrust your logistics to a truly responsible provider. How do you find one? Download our questionnaire for choosing a fulfillment partner. This guide contains 50+ questions about fulfillment services that are good to know the answers to before you sign a binding contract.

Is it financially worth it to switch to logistics outsourcing? Is logistics outsourcing a suitable solution for you? Find the answers in our e-book or our logistics calculator. Calculate how much logistics is currently costing you and find metrics to compare your total logistics costs to the cost of outsourcing logistics.