E-commerce logistics: How many goods to order from your suppliers?

Management of inventory is one of the most complex tasks when running an online store, especially so during periods of business growth. Because the larger your inventory, the more important the role of finance. Moreover, it’s increasingly challenging to keep track of the current stock or make decisions regarding further stock purchases. These issues can significantly impact the quality of your cash flow and the overall functioning of the company.

In other words, without proper inventory management, you risk:

- Excessive storage of unnecessary and obsolete goods, or goods nearing expiration.

- Inefficient allocation of financial resources, which could otherwise be used to purchase your bestsellers.

- Increased logistical costs related to warehouse space, equipment, personnel, and your time, among others.

- Stockouts.

- Losing your customers to competitors.

For ordering and following storage of goods, it’s crucial to find a balance. How much inventory should ideally be ordered from suppliers? Familiarize yourself with the concept of re-order quantity.

What is the re-order quantity?

The re-order quantity is the ideal amount of a specific product (SKU) that you are planning to order from your supplier to replenish stock.

The re-order quantity changes over time, depending on inventory turnover, planned marketing actions, seasonality, (un)planned events during the year (such as Christmas, pandemics, etc.), and possible quantity discounts from the supplier.

TIP: When ordering a particular SKU, consider whether to also order other products from the chosen supplier to save on shipping costs.

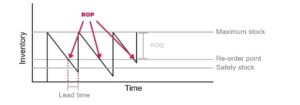

The concept of the re-order quantity is closely related to the re-order point (ROP), which is the ideal moment to create a new order from the supplier (see the mutual relationship below).

How to calculate the optimal re-order quantity in 3 steps

There are several ways, depending on the industry and context, to quantify the optimal re-order quantity. However, for e-commerce purposes, we recommend the following simplified process, which takes into account the average daily sales and the average lead time for the ordered SKU.

To calculate the optimal re-order quantity, we recommend using this formula:

Optimal re-order quantity (units) = Average daily sales (units) * Average lead time (days)

1. Average daily sales

When calculating the average daily sales, it’s ideal to consider 30 days, within a comparable annual period. For example, if you’re planning to order products for a December event like Black Friday, consider the average daily sales from the same event last year. Average daily sales are calculated in units.

For example, if during a 30-day period you sold 960 units of a specific SKU (e.g., green Kilpi brand T-shirt, size XL), then your daily average is 32 units (960 units / 30 days).

2. Average lead time

This is the time from ordering goods from your supplier to receiving the inventory at your warehouse or distribution center of your external fulfillment partner. The end of the lead time can also be set when the products are stored in position, meaning they are available for new or already received orders. Average lead time is calculated in days.

For example, if you ordered a specific SKU (e.g., green Kilpi brand T-shirt, size XL) from your supplier on June 1st and you have it available for picking by June 30th, your lead time is 29 days (30 days – 1 day).

3. Optimal batch quantity

The ideal quantity for ordering a product from your supplier is obtained by multiplying the above variables – average daily sales and average lead time.

For example, if you’re planning to order a specific SKU (e.g., green Kilpi brand T-shirt, size XL), then, in this case, your optimal re-order quantity for this SKU is 928 units (32 units * 29 days).

TIP: It’s recommended to calculate optimal re-order quantity for individual SKUs more frequently, especially during periods of increased order volume or uncertainty in the year.

Re-order quantity vs. re-order point

The concepts of re-order quantity (ROQ) and re-order point (ROP) are closely related and work in tandem. For this reason, they often interchangeably are used in practice.

As mentioned above, the re-order quantity refers to HOW MANY units of a specific SKU should ideally be ordered from the supplier. Conversely, the re-order point indicates WHEN is the most appropriate moment to place an order to ensure product availability until the arrival of new goods in the warehouse. The ROP is typically signaled by the corresponding warehouse management system (WMS), which monitors the depletion of specific SKU quantities at or below the set quantity level in real-time.

The mutual relationship between ROQ and ROP is evident from the following simplified graph.

Note: ROP consists of the so-called safety stock, which is stored for “just in case” scenarios, and demand during the lead time of a new order from the supplier.

Benefits of working with re-order quantity and re-order point

By calculating re-order quantity and re-order point, you can achieve more efficient management of your stock levels. Specifically, the following benefits are of particular interest.

1. Minimising the risk of stock-outs

Stockouts negatively impact both the customer experience with your online store and the lifetime value of your customers. The result can lead to the unpopular scenario of customers leaving to competitors.

By managing your logistics through an appropriate warehouse management system (WMS), you automatically, in addition to reaching re-order points, receive information on re-order quantity. Some WMS systems also offer the option of automatically ordering ROQ (re-order Quantity) from your suppliers.

“When we handled logistics on our own, we only had a basic overview of our inventory – not in the form of an electronic system or client application. However, by collaborating with Skladon, we were able to fully automate logistics. We wouldn’t have come close to this state ourselves, partly due to the cost of technologies in relation to our cash flow,” said Tomas Pokorny, Co-Founder Dogsie.

2. Logistics cost optimization

Using ROQ (re-order quantity) and ROP (re-order point) calculations gets you closer to the ideal inventory levels, enabling you to fulfill all incoming orders efficiently. This helps avoid excess inventory, which translates to costs inefficiently allocated to current stock, storage, equipment, personnel, etc.

If you’re not sure about what to include in logistics costs, download our e-book. In addition to individual logistic cost items, it also includes specific practical examples.

3. Easy inventory management

With ROP and ROQ, you know precisely when and how much inventory needs to be replenished. Coupled with the use of an appropriate warehouse management system (WMS), you gain accurate and up-to-date information or complete reports on your inventory management. This includes products coming to your warehouse, held in stock, or on their way to your customers.

“The greatest added value in the MySkladon client application is seen in the accurate information about our inventory and the details of individual orders,” said Simona Benkova, Process Manager Skinners.

Conclusion

From the above, it is evident that knowing the most accurate count of products for replenishing stocks is crucial for successful inventory management. With our recommendations, you can be confident that you are on the right path towards cost-effective intralogistics.

“Outsourcing logistics is one of the best steps we’ve taken in our business. It saved up a lot of time for us; we don’t have to deal with temporary workers in the warehouse or their management, and most importantly, the overall efficiency of our logistics has increased,” said Tomas Pokorny, Co-Founder Dogsie.

Cooperate with Skladon for the growth of your business

Sooner or later, you will reach a point where you will consider modernizing your logistics. At this moment, you will start asking yourself, “Should I invest in new warehouse space, technology, equipment, and personnel, or should I outsource my logistics to a fulfillment service provider?“

We recommend contacting a logistics expert, preferably an auditor, who will compare both options with a in-depth methodology. The result for you will be both a financial comparison and the definition of the advantages and disadvantages of each solution. And ultimately, it will provide a professionally supported direction for your logistics.

“In the past, logistics was a huge problem for us, which was dicussed across the company. After a logistics audit and transitioning to logistics outsourcing, it’s a service that works for us, and I know that whenever I come with anything regarding logistics, Skladon will handle it. We percieve logistics outsourcing as the right step; in many aspects, I wouldn’t have expected it to work so well,” said Pavel Kovar, Logistics Manager Kilpi.

Answers to possible concerns about fulfillment

IT connectivity and system stability

Are you worried about integrating your online store with a fulfillment partner’s warehouse system, or about system stability? Firstly, it’s important to note that technical issues can arise both in managing logistics internally and through outsourcing. Here at Skladon, we have experience in integrating both classic and custom e-commerce solutions or ERP systems. Our logistics operations are managed by a robust warehouse management system (WMS) with cloud storage. The complete integration with our system, or optimization and management of the WMS, is entirely handled by our in-house IT team, enabling us to guarantee immediate responsiveness to you.

Order processing quality and packaging

Concerned that we won’t be able to process orders with the same quality you achieve? Worried about our flexibility in packaging according to your needs? We have tailored packing processes with each of our clients, meeting specific requirements. We offer discounts on packaging materials or accuracy in order processing at 99.95% to over 160 countries.

Flexibility

Do you feel that logistics outsourcing lacks flexibility due to warehouse or personnel limitations? In our facility, we have the capacity to expand up to 19,000 sq.m., with the option to build a second floor. Our core staff, whose numbers are adjusted to our standard daily order volumes, are supplemented by over 80 temporary workers. With our current setup, we can process up to 6,000 orders per day. We are a reliable partner even during your peak sales periods.

Contractual commitment

Do you perceive a risk in the contractual commitment of logistics outsourcing? Our clients have the option to choose the contract length. If you’re not satisfied with the service offered, there’s always the possibility to terminate or not renew the contract and revert to your own / another solution. We also offer the option of partial transfer of your logistics, allowing you to assess our service with a sample of your inventory.

Loss of physical control over goods

Concerned about losing physical control over your goods when transitioning to logistics outsourcing? We have a solution for you as well. As our client, you gain access to the MySkladon application, where you have complete information about your logistics in clear dashboards, along with other functionalities described in this article. Online, in real-time, and 24/7. We believe that if logistics are performed effectively, physical visits of your management in our distribution center is unnecessary.

At Skladon, we believe in cutting-edge technologies, which we see as the future of e-commerce logistics, as well as in the personal approach of our logistics and customer care employees. No generic contacts, call centers, or automated messages. Only individuals fully understanding your logistic requirements.

Take advantage of our already established infrastructure and get a reliable partner on your side guaranteeing a logistical competitive advantage at the level of the biggest online players.

“Since January 2020, we haven’t recorded any errors in order fulfillment, given the low percentage, we consider reporting as time-inefficient. We’re set up in a way that if a significant error occurs, we directly communicate the situation with our account manager,” Simona Benkova, Process Manager Skinners.