Individual approach in fulfillment

Recently, the term “complete or comprehensive fulfillment services” has been increasingly used in the marketing communication of logistics outsourcing providers. We can come across it almost anywhere – in internet search engines, on social networks, banners, in various discussions, at conferences and exhibitions.

But what do we mean by this term? What does “complete fulfillment service” mean in practice? And how does it relate to the individual approach to individual clients who have decided to entrust their logistics to an external partner? Let’s specify it in more detail and illustrate it with specific cases.

Complete fulfillment services

The concept of fulfillment has become significantly established on the Czech e-commerce scene in recent years, following the example of more matured countries. This has been particularly helped by the COVID-19 pandemic, which has had a significant impact on the positive dynamics of e-commerce. Parallel to the awareness of fulfilment, the base and competition of fulfilment providers has also grown. And for the most part, these providers have one thing in common – offering complete fulfillment services.

The completeness of fulfillment services can be viewed from two perspectives – width and depth. While in width we look for the offer of individual logistics processes such as receiving goods, storage, picking, packing, transport, claims, returns, etc., depth represents the extended possibilities in these processes and the degree of customisation to the specific needs of a particular client. Since no two online stores are the same, neither can their wishes be identical.

For us, complete fulfillment services mean only one thing – maintaining, ideally increasing the quality of our clients’ logistics, without compromise, limitation or standardization. In other words, let’s imagine a formula:

Complete fulfillment services = handover and continuation of our own best practices + expansion of logistics capabilities + quality and competitive enhancement

In the following chapters, we will discuss examples of individual logistics processes that you may encounter in practice when working with a fulfillment provider. Although some of the examples may seem obvious at first glance, the opposite is true. After mapping the market, we concluded that the degree of customisation is based on the capabilities of the fulfilment provider, their approach to process standardisation and the specific needs of the client.

Important: For individual warehouse operations, we assume that they take place under system control with the implementing of EAN and other codes. Only in this way is the logistics partner able to maintain competitiveness and the speed and accuracy required by the market.

TIP: Before signing a contract, we recommend that you set up an SLA (Service Level Agreement) with your logistics partner, for example for the speed of order processing, the accuracy of order processing or for unexplained stock losses.

Receiving of goods

In fulfillment, this is the first step that largely influences the operation and quality in subsequent logistics operations and ultimately the (un)satisfaction of your employees and customers. In other words, you also continue to operate with what you receive in your warehouse. Therefore, we recommend that you view the good receiving process, although it may not seem so at first glance, with high importance.

With fulfilment providers, it is possible to agree on a number of extra requirements when receiving goods, in addition to the basic physical receipt. These include:

- Visual checking of the goods physically received into the warehouse from the supplier, e.g. checking for mechanical damage of boxes, presence of mould, moisture, etc.

- Quantitative check of the goods physically received into the warehouse from the supplier, where the handling units, i.e. pallets or boxes, are usually counted.

- (Random) quality checks of products received from the factory according to mutually agreed standards, which may relate to a number of characteristics such as colour, low quality, size, flavour, etc. This check is often required by clients due to the lack of physical contact with the selling goods.

- Quantitative system checks at pallet, box or product level, which then translates into stock accuracy.

Kitting

The kitting process is the finalization of the product from “semi-finished products” before being placed in storage positions. Kitting is not always part of the fulfillment service offer, which is especially true for highly standardized operations of multinational companies.

The workflow at the kitting station, together with the packing station, is usually highly individual. It is based on the specific needs of the client and on pre-agreed and mutually agreed procedures. The client’s specific wishes are literally fulfilled here on his own brand.

Two variables primarily speak to the functioning of the assembly station – frequency and complexity.

Frequency

Requests arrive at the picking station:

- Immediately upon receipt of “semi-finished goods” in the warehouse.

- On an ongoing basis according to agreed minimum / maximum quantity values of finished products on picking shelves.

- Cyclically in daily, weekly, monthly, quarterly, yearly, etc. periods.

- In batches, for example, before the launch of a marketing event.

Complexity

The kitting of final products can be a simple or more complex process. It can consist of:

- Finalizing a product from multiple “semi-finishes”, e.g. assembling into sets and kits with premium filling material and additional decoration, inserting insoles and tying shoelaces in shoes, repackaging into bags, tissue paper and branded packaging, engraving, etc.

- Attaching additional material such as leaflets, instructions, EAN code labels, batteries, etc.

- Assembly of multiple components received from different suppliers, etc.

Storage

The composition of storage racks and other equipment can vary significantly from one fulfillment provider to another, especially in relation to the sector of the stored product range. Storage and product handling requirements vary considerably across retailers, fulfillment providers may offer:

- Possibility of storing products in pallet racks due to their high volume or when holding excessive stocks.

- Possibility of storing products in shelf racks or vertical stackers for immediate picking by foot warehouse staff.

- Continuous replenishment of products from pallet to shelf racks, i.e. from long-term stocks to positions for immediate picking according to signal levels.

- Possibility of storage on single or multi SKU positions, i.e. on positions set up for storage of one or more types of products (SKUs).

- Continuous consolidation of stock to the lowest possible number of stock positions.

- Storage according to product turnover (ABC analysis), where the best-selling products are stored as close to the packing tables as possible.

- Other storage options based on product sensitivities, e.g. in coolers, freezers, locked cages with restricted access, etc.

- Carrying out regular, sensitivity or partial inventories of goods.

- Possibility of storing products received from third countries, i.e. non-EU countries, in a bonded warehouse to optimise the client’s cash flow.

- And much more.

Picking

The picking process follows immediately after the moment of order receipt. It is therefore the first process that influences the speed of delivery of the order to the end customer, and thus has its own contribution to the customer experience. There are several methods of picking in logistics, each based on the needs and size of a particular retailer. Goods can be picked according to:

- The optimal route, which represents the system-set shortest possible route to pick products from received orders.

- Different methods for material and inventory flow control. The most commonly used is the FIFO method, which always picks the earliest stocked piece of a particular product. For products with an expiry date, the FEFO method is used, where the product with the closest expiry date is considered and picked first. There are also other methods, a complete list can be found in this article.

- Allocation of specific logistics personnel for individual clients. These warehouse operators take responsibility and are evaluated for meeting the SLA (Service Level Agreement). They also have the advantage of knowing the specifics and location of the client’s goods in the warehouse space.

- Use of appropriate handling equipment. For smaller products, KLT boxes are sufficient, for bulkier products, trolleys or pallet trucks are sufficient, for heavy/oversized products, the use of forklifts is required, etc.

- Prioritization of orders at the level of each client, where, for example, picking an order for a B2B partner has higher priority than order for brick-and-mortar store.

Packaging

As mentioned earlier, packaging tends to be highly personalised in fulfilment centers. The logistics side has pre-agreed and agreed packaging procedures with the clients. In this case, it is also possible to allocate selected logistics staff for individual clients in order to maintain efficiency and a constant level of quality.

Packaging can be approached either automatically with the assistance of packaging machines or manually by humans. Each option has its (dis)advantages. The advantage of machine packing is, for example, the higher speed or the saving of cartons, which are sized exactly according to the volume of the products currently packed in the order. However, they often encounter limits related to the individualization and personalization of client requirements, which can be for example:

- Use of the client’s non-standard packaging and filling material. Custom packaging is often perceived by clients as another means of branding and evoking positive unboxing. There are also clients who use different packaging material for their highlighted premium goods than for their general merchandise. A special category is the supply and use of increasingly desirable eco-friendly material.

- Special fixation of fragile goods – liquids, glass, products made of natural materials, etc. In practice, the insertion or arrangement of additional packaging is required, etc.

- Use of branded tapes, stickers, hand-painted elements, etc.

- Inserting extras such as thank you cards, small gifts, personalised and handwritten messages in different languages depending on the destination of the package, manuals, handbooks, promotional materials, leaflets etc., often on a strictly agreed position or only for a specific product or above a certain order value.

- Packaging in random or desired order. A client-defined order is required, for example, to save time or when space is limited during the unpacking of B2B shipments in your own brick-and-mortar store.

- Attaching pallet or carton labels with the contents of the package, attaching delivery notes, invoices and other documents.

- Special packaging, recording and checking IMEI, factory or serial numbers of products, for example in the sector of more expensive electronics, etc.

Dispatch

The dispatch and delivery of orders to the end customer / user is usually outsourced by fulfillment providers to contracted carriers. Fulfillment companies rarely arrange shipping through their own transport network. However, they fully represent their clients in negotiations with carriers and take responsibility for a smooth process.

Fulfillment specialists can thus offer their clients:

- Deep know-how of domestic and foreign markets and their specifics and established standards.

- Extended offer of carriers and their products according to specific needs – economical or express carrier transport methods, carriers specializing in oversized shipments, ideal product variants for shipping to domestic, EU, third countries, etc.

- Expertise and administration related to customs procedures.

- All communication with carriers, IT connections and the strength of their negotiating position in pricing, which they gain by accumulating orders from their clients.

- Arranging and connecting other carrier capabilities and functions such as age verification at order delivering by the end customer, creating and managing COD accounts in different currencies, etc.

Returns

The returns management process, the quality of which is increasingly influencing the increase of customers’ lifetime value, tends to be a premium fulfillment service offered together with picking and packing. And like these two processes, it is also highly individual. Individual return scenarios are agreed with each client during onboarding. Fulfillment providers can thus offer their clients:

- Quantitative checking of the contents of the returned shipment, where differences with the originally sent order are detected.

- Visual checking of the returned goods for signs of use or damage.

- In borderline cases, photography of the returned goods, followed by individual communication on next steps.

- Putting the returned goods back into saleable condition – repackaging products into new packaging, ironing, etc.

- According to the assessed condition, re-shipment to the end customer, re-stocking, sending the returned goods to the client’s headquarters, disposal, etc.

Claims

Claims are in most cases a hybrid process, i.e. both customer care and customer care of fulfillment partner are involved. While the customer care of the client primarily interacts with its end customers, the customer care of the logistics partner works with the carriers who are the most frequent cause of complaints, or with its logistics colleagues, to resolve cases. In practice, the customer care department of a fulfilment partner can provide its clients with:

- Camera records proving the packaging of goods that are claimed by the customer as missing or delivered in reduced quantities.

- Financial compensation for orders damaged by the carrier, incorrectly picked by logistics personnel or otherwise delayed.

IT technologies

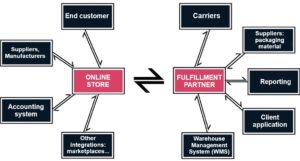

IT technology is a separate area in fulfillment that plays a significant role in modern times and especially in e-commerce. They are more or less a bridge between the retailer and the logistics partner by ensuring an automatic, immediate and two-way flow of information across the various systems and subsequently the complete supply chain. To give you an idea, we offer the following diagram.

Inventory management

By outsourcing logistics, the retailer does not lose control over its material flow or inventory. On the contrary. Fulfillment providers with an emphasis on technology spend considerable resources to ensure maximum transparency and timeliness of the data they share with their clients through client applications. These applications are then used by clients as a tool to effectively manage their inventory management.

Our clients have access to the MySkladon application, which provides a complete overview of goods receipts, stock, orders, returns and complaints in real time, 24/7, online and on any device with an internet connection.

Among other things, MySkladon also offers a range of more advanced features. For example, it notifies its users of so-called re-order points or re-order quantity. Clients thus have data-based information on when and how many products to ideally order from their suppliers. It enables the generation of detailed and customised reports that serve as a basis for defining inventory turnover in a selected time frame, custom ABC analysis or further analysing the behaviour and preferences of your customers.

Connection to other sales channels

In addition to the carriers themselves and other standard accounts used, the ability to connect to other intended sales channels that allow resellers to further expand and grow their business is important when selecting a fulfillment partner.

A good example is connections to marketplaces, whose influence will grow significantly in the Czech market in the very near future. There are over 150 online marketplaces worldwide, and in case of a client’s decision to sell on some of them, it depends on the individual capabilities and capacities of the fulfillment provider.

Join forces with Skladon

As you’ve probably already realised while reading this article, an external fulfillment partner can offer considerable width and depth to their services. Individuality and branding will play an increasingly important role in certain industries. An emphasis on quality and an open approach to new personalized requirements are important conditions for establishing a mutually beneficial cooperation. So choose carefully on your business growth path.

At Skladon, we percieve a pro-client and individual approach to our clients as one of the main pillars. While our clients can choose from the vast majority of the above, we are also open to consultation and possibly launching new scenarios and possibilities.

In a nutshell, we offer a complete fulfillment service for our clients.

Want to get a better idea of how we approach our clients’ individual requirements in our distribution center? Watch our company tour video, which will take you through our logistics guide.