How to prepare logistically for Christmas

Christmas is slowly around the corner. For the average citizen the most beautiful holiday of the year, for online stores a period of increased demand for their products, which goes hand in hand with an increase in orders, but also in overall revenue.

For many online stores, however, Christmas is also a time of stress and worry about how to manage everything. And logistics is one of the most frequently mentioned areas. Do you recognise any of the following issues?

- Do we have sufficient warehouse space for our products?

- Can we clear everything so that the goods arrive in time under our customers’ Christmas trees?

- Does our carrier have sufficient capacity to transport all packaged orders?

The above raises an important question… How do we logistically prepare for the upcoming Christmas season?

When to start preparing for Christmas?

Both online stores, carriers and customers are gradually running into the logistical limits of Christmas. That is why we at Skladon recommend thorough logistical preparation. When to start? If you want to experience the most “peaceful” peak of the season, start now!

10 of our logistics recommendations

There is no one-size-fits-all method for online stores when planning for Christmas. However, here are 10 tips to help you minimise the possibility of problems during this busy period. Tips that will guide you towards achieving the maximum potential of your business.

So what can you do to keep your customers happy?

1. Contact your suppliers in advance

Just like you, your suppliers need to pre-stock and have enough time to process their orders. This is especially true when they are planning a higher volume of goods or a larger number of orders. By creating an unannounced order, you are exposing yourself to the risk of a shortage of goods in your supplier’s warehouse, in addition to potential time delays in the delivery of goods to your warehouse.

Therefore, we recommend that you contact your suppliers in advance of your intended orders and book your anticipated volumes with them.

2. Order your goods in advance

In the first step, analyze your historical sales of each SKU from the same/similar time periods. Consider year-over-year sales trends, upcoming marketing activities, and other variables to help you determine the most accurate idea of the amount of products to order. Also, map out your best sellers or products whose sales may affect the sales of a related product (cross selling). For more detailed information on how to order your product inventory, see our other article on inventory management.

When setting a deadline for ordering goods from a supplier, be guided by mutual agreement (see previous point), its lead time and your logistics capacity. For unexpected cases, we recommend that you have other corresponding suppliers in reserve.

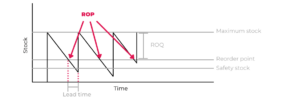

3. Work with re-order points

This point builds on the previous needs analysis. For individual SKUs, set the so-called re-order points (ROP), or quantity thresholds for individual products. When they drop to these points, you will be systematically informed of the need to re-order products from your supplier. We recommend increasing these re-order points for periods of increased demand. This will increase your so-called safety stock for products that are likely to be part of orders during the lead time for new goods to be delivered to your warehouse.

Whether working with a more advanced warehouse management system (WMS) or a technology-based logistics partner, tracking inventory, setting re-order points, and automatically notifying / ordering goods from your supplier are valuable features.

We also recommend, compared to quieter months, increasing your re-order quantity (ROQ) to comfortably meet current demand. By optimal re-order quantity, you mean the ideal quantity of products for a new order with your supplier. Note that proper inventory management has, among other things, a positive effect on your cash flow.

4. Unite your team

Be sure that your company’s various departments are informed about plans for the upcoming peak season and current events. Set up a common calendar with action steps to minimize the risk of inconsistencies. For example, include deadlines for creating orders with suppliers, completing stocking of goods, purchasing packaging and other consumables, launching marketing campaigns, etc., including staffing requirements.

This will avoid problems associated with inefficient order processing or stock-outs caused by poor internal communication.

5. Order “something extra”

Christmas is a joyful time of the year. Adjust your packaging or contents to suit. Add little surprises to your order that will delight your customer the moment they unbox the package. If you opt for imaginative and recyclable packaging, all the better. It will positively improve your customer experience, which increases the chances of a future return customer being served. In other words, you are increasing customer lifetime value (CLV).

6. Make more frequent inventories

To keep the pre-Christmas rush running smoothly, it’s important to have accurate stock levels. Whether for the actual reordering of goods from your suppliers or to reduce the frequency of unpleasant phone calls from customers to your customer service, who, for example, ordered their goods thinking that they were in stock.

We therefore recommend that you take a full inventory of your stock before ordering goods for Christmas. Ideally, you should also focus on quality control for problem products that are fragile, expired, etc. Additionally, during times of increased sales, we recommend that you also perform more frequent partial checks on high turnover items.

7. Plan with time to spare

Murphy’s Laws always work reliably. That is why all well-laid plans allow for the possibility of unforeseen events. The Christmas period is hectic for all parties involved, your goods can be delayed at any link in your e-commerce supply chain.

Prevent unnecessary problems arising from poor planning. Start your Christmas preparations today.

8. Implement an inventory management system

Keeping track of your goods flow is one of the cornerstones of a successful business. Whether you sell through a single sales channel or multichannel, use the appropriate tool to manage and record your holding.

If your business is growing, at some point you will come across the need to implement a warehouse system that meets your expanded logistics requirements. How to choose one? For starters, download our list of essential features that any advanced warehouse management software (WMS) should meet.

Looking to avoid the high upfront investment associated with acquiring a WMS and the subsequent savings associated with optimizing and maintaining it? An option may be to switch to a fulfillment specialist who is already working with such software.

9. Improve order delivery with 3PL

Nowadays, speed and accuracy in delivering goods to end customers separates successful e-shops from unsuccessful ones. For your comparison, the average picking accuracy of fulfillment companies is 99.51%.

If you’re looking for a way to speed up order delivery, we recommend working with multiple carriers that complement each other’s product offerings. Small e-shops and large fulfillment providers alike can run into capacity issues, especially during peak sales periods, so it’s always a good idea to have an alternative solution in reserve. Another way to achieve faster delivery is to set up as late as possible for carrier pickups. This will give you more room to handle orders received later on the same day.

Efficiency in the related intralogistics processes is important to achieve the highest percentage accuracy and fastest possible times. It all starts with the quality of goods received into the warehouse, followed by the picking and packing processes.

Are you looking for a solution to streamline processing and speed up the delivery of your shipments in a short time? Get in touch with a fulfillment expert. At Skladon, we maintain a standard of 99.95% picking accuracy when processing orders. We work with 20+ global and local carriers to ship orders received. Thanks to our warehouse location, we deliver orders to 4 countries within the next day (D+1 mode) by economical ground shipping and at local prices. Are you dealing with customs issues? We also offer experience in shipping products to more than 180 countries.

10. Report for next year

As well as coping with the pressures of the current Christmas, set up a method of reporting that you will then use to analyse and prepare for the next Christmas. Whether in relation to suppliers, carriers, employees, products, warehouse equipment, software, etc. Write down shortcomings, make notes and map out possible improvements. Ultimately, this will relieve your nervous system.

Get in touch with a logistics professional

Are you already thinking about how you will manage this Christmas? Not sure where to start and worried about what you’ll need to get done? Don’t want to relive the hectic days, order processing problems or carrier obstructions?

Contact us! In our warehouse, currently 16,000 sq.m., we have over 120 full-time employees ready to handle your orders, supplemented by part-time workers when needed. Their operation is controlled by a warehouse system which, in addition to the precise management of our clients’ inventory, eliminates human errors. In our flexible warehouse space, we have set up fulfillment processes precisely for e-commerce needs, which allows us to handle 10,000+ orders in an established multi-shift operation.

Focus on areas of your business other than logistics and try to maximise your sales potential. Have a logistically peaceful Christmas.